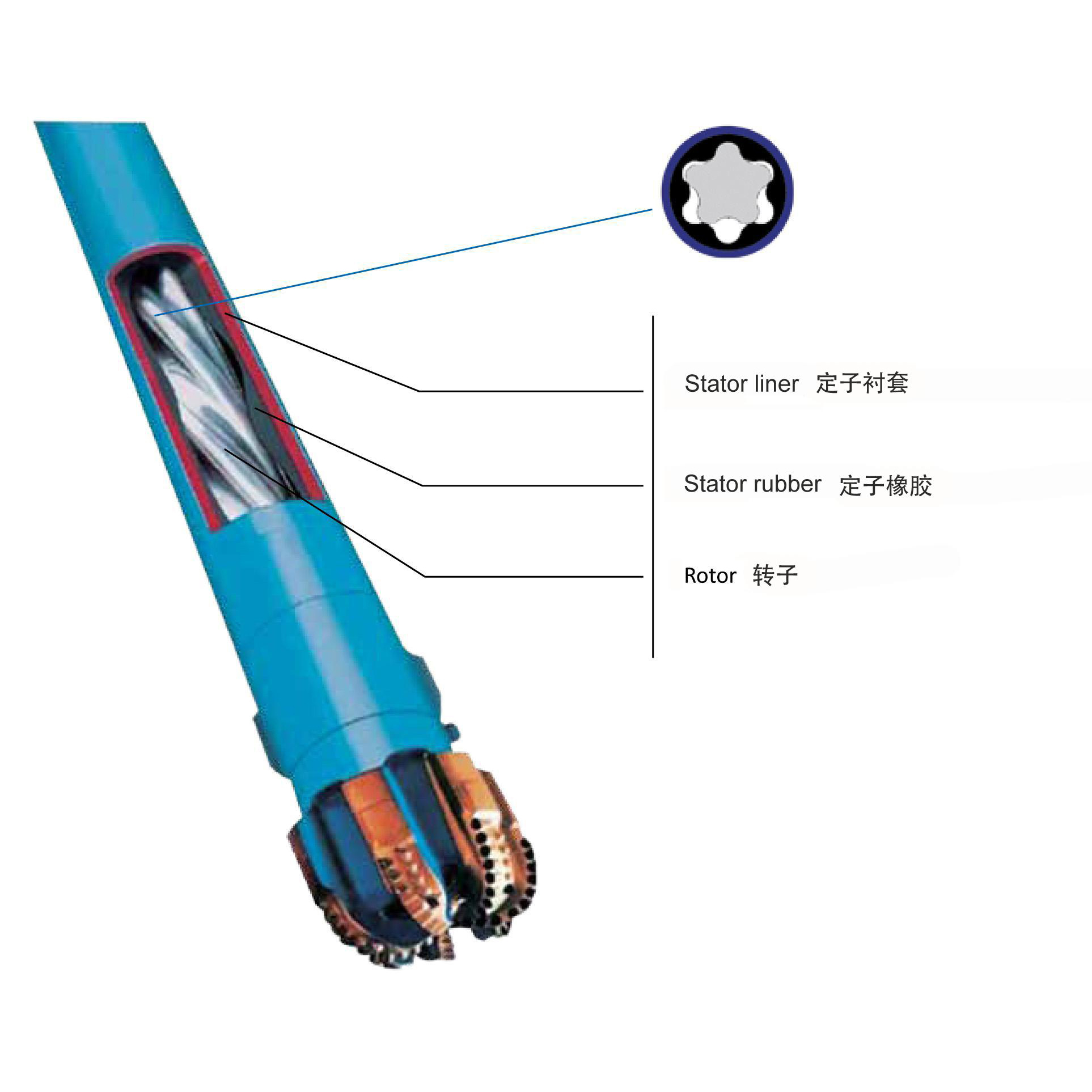

PDM Drill(downhole Motor)

Ang downhole Motor ay isang uri ng downhole power tool na kumukuha ng power mula sa fluid at pagkatapos ay isinasalin ang fluid pressure sa mekanikal na enerhiya. Kapag ang power fluid ay dumadaloy sa hydraulic motor, ang pressure difference na binuo sa pagitan ng inlet at outlet ng motor ay maaaring paikutin ang rotor sa loob ng stator, na nagbibigay ng kinakailangang torque at bilis sa drill bit para sa pagbabarena. Ang tool ng screw drill ay angkop para sa vertical, directional at horizontal wells.

Mga parameter para saPDM Mag-drill(Downhole na motor):

| Modelo | Saklaw ng daloy ng motor(l/s) |

Pagbaba ng presyon MPa(ksi) | Na-rate metalikang kuwintas Nm(ft.lb) | Max.metalikang kuwintas Nm(ft.lb) | Inirerekomenda ang bit na timbang kN(kips) |

kapangyarihan kW(HP) | Si Dia. mm(in) | Ang haba m(ft) | Mga koneksyon(API REG) | |

| 上Magkahon | 下Ibaba ang kahon | |||||||||

| 5LZ43×7.0 | 0.5~1.5 | 4(0.64) | 108(80) | 173(128) | 6(1.3) | 3.68(4.9) | 43(11/16) | 3.5(11.5) | M27×2 | |

| 5LZ60×7.0 | 1.26~3.13 | 2.5(0.4) | 160(118) | 280(207) | 5(1.1) | 2.35~6.03(3.2~8.1) | 60(2 3/8) | 3.3(10.8) | 1.9TBG | |

| 5LZ73×7.0 | 1.26~5.05 | 3.5(0.5) | 275(203) | 480(354) | 12(2.7) | 3.5~13.82(4.7~18.5) | 73(2 7/8) | 3.45(11.3) | 2 3/8TBG | 2 3/8REG |

| 5LZ89×7.0 | 2~7 | 4.1(0.6) | 560(413) | 980(723) | 18(4) | 5.6~19.35(7.5~25.9) | 89(3 1/2) | 4.67(15.3) | 2 3/8REG | |

| 5LZ95×7.0 | 4.73~11.04 | 3.2(0.5) | 950(701) | 1240(915) | 21(4.7) | 10.4~23.79(13.9~31.9) | 95(3 3/4) | 3.7(12.1) | 2 7/8REG | |

| C5LZ95×7.0 | 5~13.33 | 6.5(0.9) | 1490(1099) | 2384(1758) | 55(12.4) | 21.8~59.3(29.2~79.5) | 95(3 3/4) | 6.88(22.6) | 2 7/8REG | |

| 5LZ100×7.0 | 4.73~11.04 | 3.2(0.5) | 710(524) | 1240(915) | 21(4.7) | 10.4~23.79(13.9~31.9) | 100(3 7/8) | 4.35(14.3) | 2 7/8REG | |

| 5LZ120×7.0 | 5.78~15.8 | 2.5(0.4) | 1300(959) | 2275(1678) | 55(12.4) | 9.5~27.23(12.7~36.5) | 120(4 3/4) | 4.88(16) | 3 1/2REG | |

| C5LZ120×7.0 | 6.667~20 | 5.2(0.8) | 2500(1844) | 4000(2950) | 55(12.4) | 70.5(94.5) | 120(4 3/4) | 6.88(22.6) | 3 1/2REG | |

| D5LZ120×7.0 | 5.78~15.8 | 1.6(0.2) | 900(664) | 1440(1062) | 55(12.4) | 6.6~18.85(8.8~25.3) | 120(4 3/4) | 3.29(10.8) | 3 1/2REG | |

| 3LZ165×7.0 | 17-27 | 4.1(0.6) | 2500(1844) | 3750(2766) | 80(18) | 78.54(105.3) | 165(6 1/2) | 6.5(21.3) | 4 1/2REG | |

| 5LZ165×7.0 | 16~28(47) | 3.2(0.5) | 3200(2360) | 5600(4131) | 80(18) | 33.5~59.65(44.9~80.0) | 165(6 1/2) | 6.25(20.5) | 4 1/2REG | |

| C5LZ165×7.0 | 18.93~37.85 | 3.2(0.5) | 3660(2710) | 5856(4319) | 100(22.5) | 112.6(151.0) | 165(6 1/2) | 6.71(22) | 4 1/2REG | |

| D7LZ165×7.0 | 18-28 | 2.5(0.4) | 2300(1696) | 3680(2714) | 80(18) | 30.4~47.2(40.8~63.3) | 165(6 1/2) | 4.7(15.4) | 4 1/2REG | |

| 9LZ165×7.0 | 19~31.6 | 2.5(0.4) | 3200(2360) | 5600(4130) | 100(22.5) | 45.24(60.7) | 165(6 1/2) | 5.7(18.7) | 4 1/2REG | |

| 5LZ172×7.0 | 18.9 ~37.8 | 3.2(0.5) | 3660(2710) | 5856(4319) | 100(22.5) | 38.3~76.6(514~102.7) | 172(64 3/4) | 6.71(22) | 4 1/2REG | |

| C5LZ172×7.0 | 18.9 ~37.8 | 6(0.9) | 6870(5067) | 10992(8108) | 170(38.2) | 71.9~144(96.4~193.1) | 172(64 3/4) | 9.18(30.1) | 4 1/2REG | |

| 5LZ197×7.0 | 22~36(55) | 3.2(0.5) | 5000(3688) | 8750(6454) | 120(27) | 49.7~78.54(66.6~105.3) | 197(74 3/4) | 6.9(22.6) | 5 1/2REG | 6 5/8REG |

| C5LZ203×7.0 | 22~36 | 5.2(0.8) | 8890(6557) | 14220(10489) | 145(32.6) | 150(201.1) | 203(8) | 8.7(28.5) | 5 1/2REG | 6 5/8REG |

| C3LZ216×7.0 | 28 ~ 56.78 | 5.0(0.7) | 7930(5849) | 12700(9368) | 200(45) | 240.8(322.9) | 216(8 1/2) | 8.285(27.2) | 6 5/8REG | 6 5/8REG |

| C5LZ216×7.0 | 28 ~56.78 | 5.0(0.7) | 10700(7892) | 17100(12613) | 200(45) | 235.3(315.5) | 216(8 1/2) | 8.285(27.2) | 6 5/8REG | 6 5/8REG |

| 3LZ244×7.0 | 18.93 ~56.78 | 5.0(0.7) | 7040(5193) | 11260(8305) | 210(47.2) | 213.8(286.7) | 244(9 5/8) | 7.56(24.8) | 6 5/8REG | 6 5/8REG |

| 5LZ244×7.0 | 50.5~75.7 | 2.5(0.4) | 9300(6860) | 16275(12004) | 213(47.9) | 87.7~136.3(117.6~182.8) | 244(9 5/8) | 7.8(25.6) | 6 5/8REG | 7 5/8REG |